Alexander's Star: Difference between revisions

en>Dimartorell Fixed Adam Alexander link (eliminated) |

en>Addbot m Bot: Migrating 4 interwiki links, now provided by Wikidata on d:q1267127 (Report Errors) |

||

| Line 1: | Line 1: | ||

[[File:Roll forming.png|thumb|Bending along rolls]] | |||

'''Roll forming''', also spelled '''rollforming''', is a continuous bending operation in which a long strip of [[sheet metal]] (typically coiled [[steel]]) is passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section profile is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities. | |||

== Overview == | |||

[[File:Flower Pattern.jpg|thumb|Flower pattern]]A variety of cross-section profiles can be produced, but each profile requires a carefully crafted set of roll tools. Design of the rolls starts with a '''flower pattern''', which is the sequence of profile cross-sections, one profile for each stand of rolls. The roll contours are then derived from the flower pattern profiles. Because of the high cost of the roll sets, [[Finite element analysis|computer simulation]] is often used to develop or validate the roll designs and optimize the forming process to minimize the number of stands and material stresses in the final product. | |||

Roll formed sections may have advantages over extrusions of a similar shapes. Roll formed parts may be much lighter, with thinner walls possible than in the extrusion process, and stronger, having been work hardened in a cold state. Parts can be made having a finish or already painted. In addition, the roll forming process is more rapid and takes less energy than extrusion. | |||

Roll forming machines are available that produce shapes of different sizes and material thicknesses using the same rolls. Variations in size are achieved by making the distances between the rolls variable by manual adjustment or computerized controls, allowing for rapid changeover. These specialized mills are prevalent in the [[Steel_frame#Light_steel_framing|light gauge framing]] industry where metal studs and tracks of standardized profiles and thicknesses are used. For example a single mill may be able to produce metal studs of different web (e.g. 3-5/8" to 14"), flange (e.g. 1-3/8" to 2-1/2") and lip (e.g. 3/8" to 5/8") dimensions, from different gauges (e.g. 20 to 12 GA) of galvanized steel sheet. | |||

Roll forming lines can be set up with multiple configurations to punch and cut off parts in a continuous operation. For cutting a part to length, the lines can be set up to use a pre-cut die where a single blank runs through the roll mill, or a post-cut die where the profile is cutoff after the roll forming process. Features may be added in a hole, notch, embossment, or shear form by punching in a roll forming line. These part features can be done in a pre-punch application (before roll forming starts), in a mid-line punching application (in the middle of a roll forming line/process) or a post punching application (after roll forming is done). Some roll forming lines incorporate only one of the above punch or cutoff applications, others incorporate some or all of the applications in one line. | |||

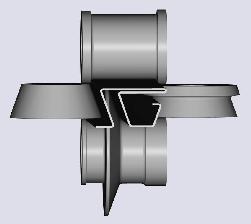

[[File:Zg-prof.jpg|thumb|left|Cluster roll set]] | |||

===Process=== | |||

The process of roll forming is one of the simpler manufacturing processes. It typically begins with a large coil of sheet metal, between 1 in. and 20in. in width, and 0.004 in. and 0.125 in. thick, supported on an uncoiler. The strip is fed through an entry guide to properly align the material as it passes through the rolls of the mill, each set of rolls forming a bend until the material reaches its desired shape. Roll sets are typically mounted one over the other on a pair of horizontal parallel shafts supported by a stand(s). Side rolls and cluster rolls may also be used to provide greater precision and flexibility and to limit stresses on the material. The shaped strips can be cut to length ahead of a roll forming mill, between mills, or at the end of the roll forming line. | |||

===Geometric Possibilities=== | |||

The geometric possibilities can be very broad and even include enclosed shapes so long as it is the same cross-section throughout. Typical sheeting thicknesses range from 0.004in. to 0.125in., but they can exceed that. Length is almost unaffected by the rolling process. The part widths typically aren't smaller than 1in. however they can exceed 20in. The primary limitation is profile depth, which is generally limited to less than 4in and rarely larger than 6in due to roll-imparted stresses and surface speed differentials that increase with depth. | |||

*Tolerances can typically be held within ±0.015in. for the width of the cross-sectional form, and ±0.060in. for its depth.<ref name="Todd">Manufacturing Processes Reference Guide, Industrial Press Inc., 1994.</ref> | |||

===Production Rates=== | |||

The production rate depends greatly on the material thickness and the bend radius, it is also affected by the number of stations or steps required. For bend radii of 50 times the material thickness of a low carbon steel .07 in thick can range from 85 feet per minute through eight stations to 55 feet per minute through 12 stations or 50 feet per minute through 22 stations.<br /> | |||

The time taken for one product to take shape can be represented by a simple function. The function is as follows: <math>Forming time = [L+n(d)]/V</math> where V is the velocity of strip through rolls (fpm), L is the length of the piece being rolled (ft), d is the distance between forming stands (ft), and n is the number of forming stands.<ref name="Todd"/> | |||

In general roll forming lines can run from 5 feet per minute to 500 + depending on the application. In some cases the limiting factor is the punching or cutoff applications. | |||

===Other Considerations=== | |||

While dealing with manufacturing, there are always things to be considered such as lubrication, the effect of the process on material properties, cost, and of course safety. <br />Lubrication provides an essential barrier between the roll dies and the workpiece surface. They help to reduce the tool wear, and allow things to move along faster. This table shows the different kinds of lubricants, their application, and the ideal metals to use them on. | |||

{| class="wikitable" border="1" | |||

|- | |||

! Work Material | |||

! Roll Lubricants | |||

! Application | |||

|- | |||

| Nonferrous | |||

| Chlorinated oils or waxes, mineral oils | |||

| Spray, wiping roller | |||

|- | |||

| Ferrous | |||

| Water-soluble oils | |||

| Wiping, drip, spray | |||

|- | |||

| Stainless steels | |||

| Chlorinated oils or waxes | |||

| Wiping roller | |||

|- | |||

| Polished surfaces | |||

| Plastic film | |||

| Calendaring, covering, spraying | |||

|- | |||

| Precoated materials | |||

| Film/forced air | |||

| | |||

|} | |||

<br />The effects of the process on the material's properties for this process are minimal. The physical and chemical properties virtually have no change. But the process may cause workhardening, microcracks, or thinning at bends when discussing the mechanical properties of the material.<br />The cost of roll forming is relatively low. Some things to be considered when calculating the cost of the process are setup time, equipment and tool costs, load/unload time, direct labor rate, overhead rate, and the amortization of equipment and tooling.<br />Safety is also a bit of an issue with this process. The main hazards that need to be taken into consideration are dealing with moving workpieces (up to 800 fpm), high pressure rolls, or sharp, sheared metal edges.<ref name="Todd"/> | |||

==See also== | |||

*[[Sheet metal]] | |||

*[[Skin-pass]] | |||

*[[Structural shape rolling]] | |||

*[[Tube beading]] | |||

*[[Roll bender|Roll bending]] | |||

==References== | |||

===Notes=== | |||

{{reflist}} | |||

===Bibliography=== | |||

* Halmos, George T. Roll Forming Handbook, CRC Press, 2005. ISBN 0-8247-9563-6 | |||

* {{cite journal | last = Dobrev | first = Atanas | coauthors = George T. Halmos | title = Roll forming into the 21st century | year = 1993 | publisher = Society of Manufacturing Engineers}} | |||

* {{cite book | last = Todd | first = Robert | title = Manufacturing Processes Reference Guide | publisher = Industrial Press inc. | location = New York | year = 1994 | isbn = 0-8311-3049-0}} | |||

==External links== | |||

* [http://www.youtube.com/watch?feature=player_embedded&v=k6iODHla6qY Informative video explaining what roll forming is.] | |||

* [http://www.industrial-machinery-news.com/pdf/COPRA-FEA-article-in-MCN.pdf Creating Real-world Situations with Dynamic Simulation Software] | |||

* [http://www.ubeco.com/files/QuManRFDes.pdf Quality Management in Rollform Design]. | |||

* [http://www.oehppos.ru/roll_forming_terms_glossary.htm Pictorial roll forming glossary in four languages: English, Russian, French, and German] | |||

* [http://www.thefabricator.com/tc/rollforming Related Roll Forming news, articles and books.] | |||

* [http://www.autosteel.org/~/media/Files/Autosteel/Great%20Designs%20in%20Steel/GDIS%202011/21%20-%20Albert%20Sedlmaier%20-%203D%20Flexible%20Roll%20Forming.ashx New Technology of CNC/3D Roll Forming - a presentation at Steel Market Development Institute Detroit 2011] | |||

{{DEFAULTSORT:Roll Forming}} | |||

[[Category:Metal forming]] | |||

[[Category:Fabrication (metal)]] | |||

Revision as of 17:21, 28 February 2013

Roll forming, also spelled rollforming, is a continuous bending operation in which a long strip of sheet metal (typically coiled steel) is passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section profile is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.

Overview

A variety of cross-section profiles can be produced, but each profile requires a carefully crafted set of roll tools. Design of the rolls starts with a flower pattern, which is the sequence of profile cross-sections, one profile for each stand of rolls. The roll contours are then derived from the flower pattern profiles. Because of the high cost of the roll sets, computer simulation is often used to develop or validate the roll designs and optimize the forming process to minimize the number of stands and material stresses in the final product.

Roll formed sections may have advantages over extrusions of a similar shapes. Roll formed parts may be much lighter, with thinner walls possible than in the extrusion process, and stronger, having been work hardened in a cold state. Parts can be made having a finish or already painted. In addition, the roll forming process is more rapid and takes less energy than extrusion.

Roll forming machines are available that produce shapes of different sizes and material thicknesses using the same rolls. Variations in size are achieved by making the distances between the rolls variable by manual adjustment or computerized controls, allowing for rapid changeover. These specialized mills are prevalent in the light gauge framing industry where metal studs and tracks of standardized profiles and thicknesses are used. For example a single mill may be able to produce metal studs of different web (e.g. 3-5/8" to 14"), flange (e.g. 1-3/8" to 2-1/2") and lip (e.g. 3/8" to 5/8") dimensions, from different gauges (e.g. 20 to 12 GA) of galvanized steel sheet.

Roll forming lines can be set up with multiple configurations to punch and cut off parts in a continuous operation. For cutting a part to length, the lines can be set up to use a pre-cut die where a single blank runs through the roll mill, or a post-cut die where the profile is cutoff after the roll forming process. Features may be added in a hole, notch, embossment, or shear form by punching in a roll forming line. These part features can be done in a pre-punch application (before roll forming starts), in a mid-line punching application (in the middle of a roll forming line/process) or a post punching application (after roll forming is done). Some roll forming lines incorporate only one of the above punch or cutoff applications, others incorporate some or all of the applications in one line.

Process

The process of roll forming is one of the simpler manufacturing processes. It typically begins with a large coil of sheet metal, between 1 in. and 20in. in width, and 0.004 in. and 0.125 in. thick, supported on an uncoiler. The strip is fed through an entry guide to properly align the material as it passes through the rolls of the mill, each set of rolls forming a bend until the material reaches its desired shape. Roll sets are typically mounted one over the other on a pair of horizontal parallel shafts supported by a stand(s). Side rolls and cluster rolls may also be used to provide greater precision and flexibility and to limit stresses on the material. The shaped strips can be cut to length ahead of a roll forming mill, between mills, or at the end of the roll forming line.

Geometric Possibilities

The geometric possibilities can be very broad and even include enclosed shapes so long as it is the same cross-section throughout. Typical sheeting thicknesses range from 0.004in. to 0.125in., but they can exceed that. Length is almost unaffected by the rolling process. The part widths typically aren't smaller than 1in. however they can exceed 20in. The primary limitation is profile depth, which is generally limited to less than 4in and rarely larger than 6in due to roll-imparted stresses and surface speed differentials that increase with depth.

- Tolerances can typically be held within ±0.015in. for the width of the cross-sectional form, and ±0.060in. for its depth.[1]

Production Rates

The production rate depends greatly on the material thickness and the bend radius, it is also affected by the number of stations or steps required. For bend radii of 50 times the material thickness of a low carbon steel .07 in thick can range from 85 feet per minute through eight stations to 55 feet per minute through 12 stations or 50 feet per minute through 22 stations.

The time taken for one product to take shape can be represented by a simple function. The function is as follows: where V is the velocity of strip through rolls (fpm), L is the length of the piece being rolled (ft), d is the distance between forming stands (ft), and n is the number of forming stands.[1]

In general roll forming lines can run from 5 feet per minute to 500 + depending on the application. In some cases the limiting factor is the punching or cutoff applications.

Other Considerations

While dealing with manufacturing, there are always things to be considered such as lubrication, the effect of the process on material properties, cost, and of course safety.

Lubrication provides an essential barrier between the roll dies and the workpiece surface. They help to reduce the tool wear, and allow things to move along faster. This table shows the different kinds of lubricants, their application, and the ideal metals to use them on.

| Work Material | Roll Lubricants | Application |

|---|---|---|

| Nonferrous | Chlorinated oils or waxes, mineral oils | Spray, wiping roller |

| Ferrous | Water-soluble oils | Wiping, drip, spray |

| Stainless steels | Chlorinated oils or waxes | Wiping roller |

| Polished surfaces | Plastic film | Calendaring, covering, spraying |

| Precoated materials | Film/forced air |

The effects of the process on the material's properties for this process are minimal. The physical and chemical properties virtually have no change. But the process may cause workhardening, microcracks, or thinning at bends when discussing the mechanical properties of the material.

The cost of roll forming is relatively low. Some things to be considered when calculating the cost of the process are setup time, equipment and tool costs, load/unload time, direct labor rate, overhead rate, and the amortization of equipment and tooling.

Safety is also a bit of an issue with this process. The main hazards that need to be taken into consideration are dealing with moving workpieces (up to 800 fpm), high pressure rolls, or sharp, sheared metal edges.[1]

See also

References

Notes

43 year old Petroleum Engineer Harry from Deep River, usually spends time with hobbies and interests like renting movies, property developers in singapore new condominium and vehicle racing. Constantly enjoys going to destinations like Camino Real de Tierra Adentro.

Bibliography

- Halmos, George T. Roll Forming Handbook, CRC Press, 2005. ISBN 0-8247-9563-6

- One of the biggest reasons investing in a Singapore new launch is an effective things is as a result of it is doable to be lent massive quantities of money at very low interest rates that you should utilize to purchase it. Then, if property values continue to go up, then you'll get a really high return on funding (ROI). Simply make sure you purchase one of the higher properties, reminiscent of the ones at Fernvale the Riverbank or any Singapore landed property Get Earnings by means of Renting

In its statement, the singapore property listing - website link, government claimed that the majority citizens buying their first residence won't be hurt by the new measures. Some concessions can even be prolonged to chose teams of consumers, similar to married couples with a minimum of one Singaporean partner who are purchasing their second property so long as they intend to promote their first residential property. Lower the LTV limit on housing loans granted by monetary establishments regulated by MAS from 70% to 60% for property purchasers who are individuals with a number of outstanding housing loans on the time of the brand new housing purchase. Singapore Property Measures - 30 August 2010 The most popular seek for the number of bedrooms in Singapore is 4, followed by 2 and three. Lush Acres EC @ Sengkang

Discover out more about real estate funding in the area, together with info on international funding incentives and property possession. Many Singaporeans have been investing in property across the causeway in recent years, attracted by comparatively low prices. However, those who need to exit their investments quickly are likely to face significant challenges when trying to sell their property – and could finally be stuck with a property they can't sell. Career improvement programmes, in-house valuation, auctions and administrative help, venture advertising and marketing, skilled talks and traisning are continuously planned for the sales associates to help them obtain better outcomes for his or her shoppers while at Knight Frank Singapore. No change Present Rules

Extending the tax exemption would help. The exemption, which may be as a lot as $2 million per family, covers individuals who negotiate a principal reduction on their existing mortgage, sell their house short (i.e., for lower than the excellent loans), or take part in a foreclosure course of. An extension of theexemption would seem like a common-sense means to assist stabilize the housing market, but the political turmoil around the fiscal-cliff negotiations means widespread sense could not win out. Home Minority Chief Nancy Pelosi (D-Calif.) believes that the mortgage relief provision will be on the table during the grand-cut price talks, in response to communications director Nadeam Elshami. Buying or promoting of blue mild bulbs is unlawful.

A vendor's stamp duty has been launched on industrial property for the primary time, at rates ranging from 5 per cent to 15 per cent. The Authorities might be trying to reassure the market that they aren't in opposition to foreigners and PRs investing in Singapore's property market. They imposed these measures because of extenuating components available in the market." The sale of new dual-key EC models will even be restricted to multi-generational households only. The models have two separate entrances, permitting grandparents, for example, to dwell separately. The vendor's stamp obligation takes effect right this moment and applies to industrial property and plots which might be offered inside three years of the date of buy. JLL named Best Performing Property Brand for second year running

The data offered is for normal info purposes only and isn't supposed to be personalised investment or monetary advice. Motley Fool Singapore contributor Stanley Lim would not personal shares in any corporations talked about. Singapore private home costs increased by 1.eight% within the fourth quarter of 2012, up from 0.6% within the earlier quarter. Resale prices of government-built HDB residences which are usually bought by Singaporeans, elevated by 2.5%, quarter on quarter, the quickest acquire in five quarters. And industrial property, prices are actually double the levels of three years ago. No withholding tax in the event you sell your property. All your local information regarding vital HDB policies, condominium launches, land growth, commercial property and more

There are various methods to go about discovering the precise property. Some local newspapers (together with the Straits Instances ) have categorised property sections and many local property brokers have websites. Now there are some specifics to consider when buying a 'new launch' rental. Intended use of the unit Every sale begins with 10 p.c low cost for finish of season sale; changes to 20 % discount storewide; follows by additional reduction of fiftyand ends with last discount of 70 % or extra. Typically there is even a warehouse sale or transferring out sale with huge mark-down of costs for stock clearance. Deborah Regulation from Expat Realtor shares her property market update, plus prime rental residences and houses at the moment available to lease Esparina EC @ Sengkang - 20 year-old Real Estate Agent Rusty from Saint-Paul, has hobbies and interests which includes monopoly, property developers in singapore and poker. Will soon undertake a contiki trip that may include going to the Lower Valley of the Omo.

My blog: http://www.primaboinca.com/view_profile.php?userid=5889534

External links

- Informative video explaining what roll forming is.

- Creating Real-world Situations with Dynamic Simulation Software

- Quality Management in Rollform Design.

- Pictorial roll forming glossary in four languages: English, Russian, French, and German

- Related Roll Forming news, articles and books.

- New Technology of CNC/3D Roll Forming - a presentation at Steel Market Development Institute Detroit 2011

![{\displaystyle Formingtime=[L+n(d)]/V}](https://wikimedia.org/api/rest_v1/media/math/render/svg/164435f1fac856d907ad03d7a486675ef47fcfa8)