Chan's algorithm: Difference between revisions

en>Altenmann Reverted good faith edits by Aboeing (talk): No need to list all articles from the category. (TW) |

Cleanup WP:COI self citations by Special:Contributions/122.216.15.84. |

||

| Line 1: | Line 1: | ||

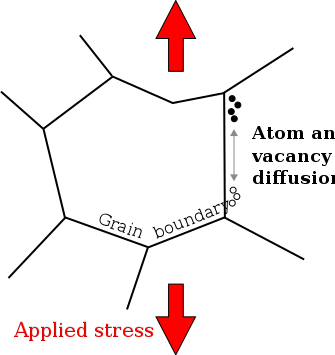

[[Image:CobleCreepgraindiagram.svg|frame|A diagram showing how atoms and vacancies move through a grain as the mechanism of Coble creep]] | |||

'''Coble creep''', a form of [[diffusion creep]], is a mechanism for [[Deformation (engineering)|deformation]] of [[crystalline]] [[solid]]s. Coble creep occurs through the diffusion of atoms in a material along the [[grain boundaries]], which produces a net flow of material and a sliding of the grain boundaries. | |||

Coble creep is named after [[Robert L. Coble]], who first reported his theory of how materials [[Creep (deformation)|creep]] over time in 1962 in the Journal of Applied Physics [http://scitation.aip.org/getabs/servlet/GetabsServlet?prog=normal&id=JAPIAU000034000006001679000001&idtype=cvips&gifs=yes]. | |||

The strain rate in a material experiencing Coble creep is given by: | |||

:<math> \frac{d\epsilon}{dt}= \frac{\sigma}{d^3} D_{gb} e^{-Q_{Coble}/RT}</math> | |||

where | |||

*<math>\sigma</math> is the applied stress | |||

*<math>d</math> is the average grain boundary diameter | |||

*<math>D_{gb}</math> is the diffusion coefficient in the grain boundary | |||

*<math>-Q_{Coble}</math> is the activation energy for Coble creep | |||

*<math>R</math> is the molar gas constant | |||

*<math>T</math> is the temperature in kelvins | |||

Note that in Coble creep, the strain rate <math>\frac{d\epsilon}{dt}</math> is proportional to the applied stress <math>\sigma</math>; the same relationship is found for [[Nabarro-Herring creep]]. However, the two mechanisms differ in their relationship between the strain rate and grain size <math>d</math>. In Coble creep, the strain rate is proportional to <math>d^{-3}</math>, whereas the strain rate in Nabarro-Herring creep is proportional to <math>d^{-2}</math>. Researchers commonly use these relationships to determine which mechanism is dominant in a material; by varying the grain size and measuring how the strain rate is affected, they can determine the value of <math>n</math> in <math>\frac{d\epsilon}{dt}~\alpha ~d^n</math> and conclude whether Coble or Nabarro-Herring creep is dominant[1]. | |||

==References== | |||

(1) Meyers and Chawla (1999): "Mechanical Behavior of Materials," 555-557. | |||

[[Category:Materials degradation]] | |||

Revision as of 23:09, 29 May 2013

Coble creep, a form of diffusion creep, is a mechanism for deformation of crystalline solids. Coble creep occurs through the diffusion of atoms in a material along the grain boundaries, which produces a net flow of material and a sliding of the grain boundaries.

Coble creep is named after Robert L. Coble, who first reported his theory of how materials creep over time in 1962 in the Journal of Applied Physics [1].

The strain rate in a material experiencing Coble creep is given by:

where

- is the applied stress

- is the average grain boundary diameter

- is the diffusion coefficient in the grain boundary

- is the activation energy for Coble creep

- is the molar gas constant

- is the temperature in kelvins

Note that in Coble creep, the strain rate is proportional to the applied stress ; the same relationship is found for Nabarro-Herring creep. However, the two mechanisms differ in their relationship between the strain rate and grain size . In Coble creep, the strain rate is proportional to , whereas the strain rate in Nabarro-Herring creep is proportional to . Researchers commonly use these relationships to determine which mechanism is dominant in a material; by varying the grain size and measuring how the strain rate is affected, they can determine the value of in and conclude whether Coble or Nabarro-Herring creep is dominant[1].

References

(1) Meyers and Chawla (1999): "Mechanical Behavior of Materials," 555-557.